Xiao Daughter Board -> Xiao Module

Solder wires between J1, J2, J3, J4, J5, J6, J7 & J9 of the daughter board to the respective solder tags on the Xiao module. The holes roughly align but will be at a small angle with respect to the boards. As the KiCAD drawing above depicts, the connections are:

J1 - D10

J2 - 5V

J3 - Batt+ Note: An insulated wire needs to pass through the Xiao D2 solder hole to the back of the Xiao

J4 - D1

J5 - SCL

J6 - SDA

J7 - 3V3

J9 - GND

Sensors Soldered Together with Flying Wires

( +, - , SDA , SCA to Daughter Board)

Use double-sided tape to attach the DPS310 PCB to the SDP31 PCB.

3D Print a soldering jig from the Onshape drawing here: Onshape Nose_Jig

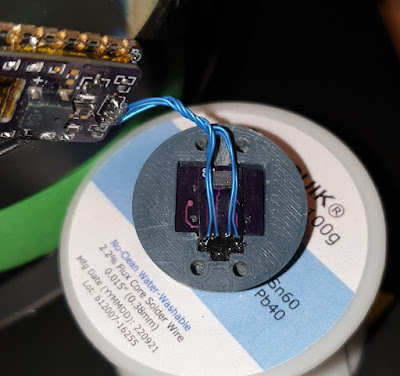

Insert the boards and run wires like this:

With all 4 wires run, solder them and trim the wire-ends at the SHT45 PCB:

For testing outside an enclosure - the wires connect from the Sensor-PCBs to the Xiao Daughter Board 1 to 1. Be sure to start at GND, which is a square solder hole (the other three are round):

If installing into the Onshape 3D printed enclosure, insert the Xiao|Daughter Board combo into the middle section of the probe enclosure:

Here is how the PCB's slot into the nose section:

UPDATE August 2023

I found the RF-can of the Xiao board could easily short out connections if not carefully insulated. Therefore I am now insulating the can with Polyimide (Kapton) tape. Picture:

Now is a good time to solder-connect the sensors to make sure all is working:

Here is current draw in normal operation (BT connection established & transmitting data):

Prepare the slide switch by soldering wires and heatshrink covering:

Note the air-gap above the Temp/Hum sensor. This needs to be filled so the enclosure does not pressurise and affect the barometric sensor (thank you Bernd from TotalVario!). I use Star brite liquid electrical tape:

Fill the aforementioned gap and allow to cure:

Before assembling there are two new tasks I had not anticipated (again thanks Bernd).

The first is to add pitot-like static pressure holes. I have created a jig on Onshape for this. The holes are 0.5mm and there are four of them (just like the static-pressure pitot tube)

.The second is to add Xiao reset connections if wanting to re-program the Xiao. Otherwise, disassembly may be required. There is also a jig for this on Onshape.

.The second is to add Xiao reset connections if wanting to re-program the Xiao. Otherwise, disassembly may be required. There is also a jig for this on Onshape.

I used the pins of an IC socket (machined type, not folded):

Power ON via the slide switch. You should hear the startup tones. Connect to BT on your phone and you should then hear a short 'connection successful tone'.

Test with TotalVario.

Programming

To finish, here is a reset push-button switch connected:

To finish, here is a reset push-button switch connected: